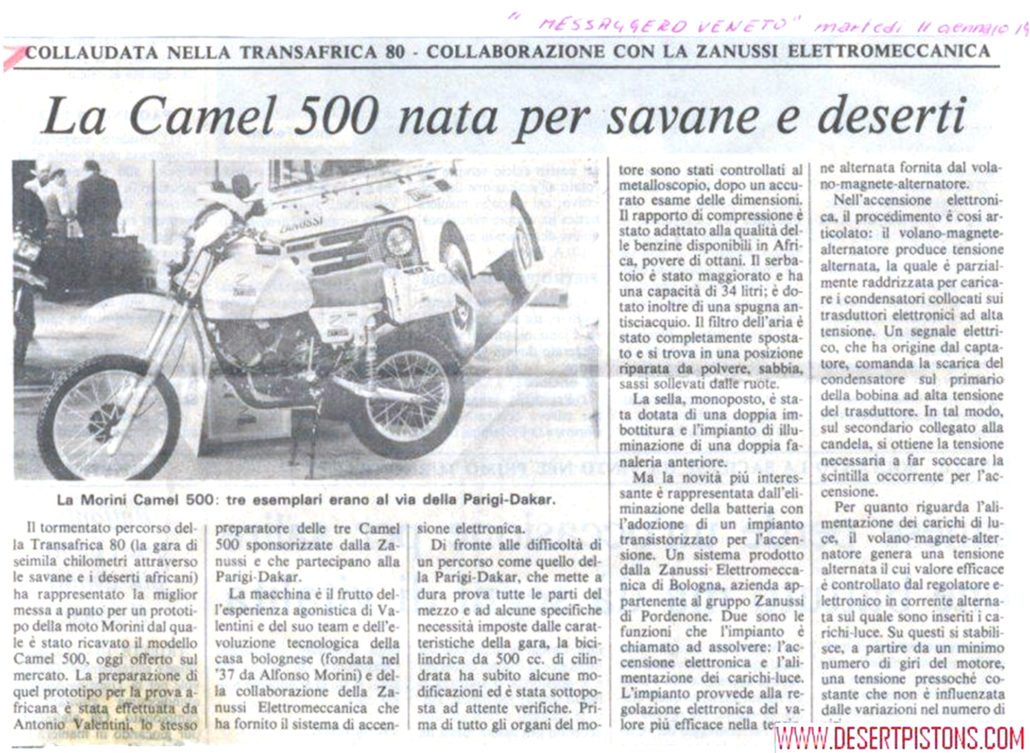

DAKAR 1983 | Le Morini Camel 500 tre esemplari erano al via della Parigi-Dakar.

Fonte: Messaggero Veneto e Desert Pistons

Il tormentato percorso della Transafrica 80 (la gara di seimila chilometri attraverso le savane e i deserti africani) ha rappresentato la miglior messa a punto per un prototipo della moto Morini dal quale è stato ricavato il modello Carne! 500, oggi offerto sul mercato. La preparazione di quel prototipo per la prova africana e stata effettuata da Antonio Valentini, lo stesso preparatore delle tre Camel 500 sponsorizzate dalla Za nussi e che partecipano alla Parigi-Dakar. La macchina è il frutto del l’esperienza agonistica di Valentini e del suo team e dell’evoluzione tecnologica della casa bolognese (fondata nel ’37 da Alfonso Morini) e della collaborazione della Zanussi Elettromeccanica che ha fornito il sistema di accensione elettronica.

COLLAUDATA NELLA TRANSAFRICA 80 IN COLLABORAZIONE CON LA ZANUSSI ELETTROMECCANICA

Di fronte alle difficoltà di un percorso come quello della Parigi-Dakar, che mette a dura prova tutte le parti del mezzo e ad alcune specifiche necessità imposte dalle caratteristiche della gara, la bicilindrica da 500 cc. di cilindrata ha subito alcune modificazioni ed è stata sottoposta ad attente verifiche. Prima di tutto gli organi del motore sono stati controllati al metalloscopio, dopo un accurato esame delle dimensioni. Il rapporto di compressione è stato adattato alla qualità delle benzine disponibili in Africa, povere di ottani.

Il serbatoio è stato maggiorato e ha una capacità di 34 litri: è dotato inoltre di una spugna antisciacquio. Il filtro dell’aria è stato completamente spostato e si trova in una posizione riparata da polvere, sabbia. sassi sollevati dalle ruote La sella, monoposto. è stata dotata di una doppia imbottitura e l’impianto di illuminazione di una doppia fanaleria anteriore. Ma la novità piú interessante è rappresentata dall’eliminazione della batteria con l’adozione di un impianto transistorizzato per l’accensione. Un sistema prodotto dalla Zanussi Elettromeccanica di Bologna, azienda appartenente al gruppo Zanussi di Pordenone.

Due sono le funzioni che l’impianto è chiamato ad assolvere: l’accensione elettronica e l’alimentazione dei carichi luce. L’impianto provvede alla regolazione elettronica del valore più efficace nella tensione alternata fornita dal volano-magnete-alternatore. Nell’accensione elettroni-ca. il procedimento è cosi articolato: il volano-magnete-alternatore produce tensione alternata, la quale è parzialmente raddrizzata per caricare i condensatori collocati sui trasduttori elettronici ad alta tensione. Un segnale elettrico, che ha origine dal captatore, comanda la scarica del condensatore sul primario della bobina ad alta tensione del trasduttore.

In tal modo. sul secondario collegato alla candela, si ottiene la tensione necessaria a far scoccare la scintilla occorrente per l’accensione. Per quanto riguarda l’alimentazione dei carichi di luce. Il volano-magnete-alternatore genera una tensione alternata il cui valore efficace e controllato dal regolatore elettronico in corrente alternata sul quale sono inseriti i carichi-luce. Su questi si stabilisce, a partire da un minimo numero di giri del motore. una tensione pressoché costante che non è influenzata dalle variazioni nel numero del motore.